Did you know that Nexstar’s Workforce Development Coaches offer onsite training? Recently, we sat down with Workforce Development Coach (and HVAC technical subject matter expert!) Joe DeLong to learn more about how “onsites” work. Here’s what Joe had to say!

Q: There are so many positives when it comes to in-person, hands-on learning in the trades. Given your level of experience, what are one or two key benefits you’ve observed?

A: One benefit to hands-on learning is that most technicians are kinesthetic learners. They need to work on things with their hands. Hands-on learning is a two-step process. First, a technician needs to learn the “why” behind whatever subject you’re trying to teach them. If they don’t understand the “why” behind it, they have difficulty understanding why a skill needs to be done a certain way.

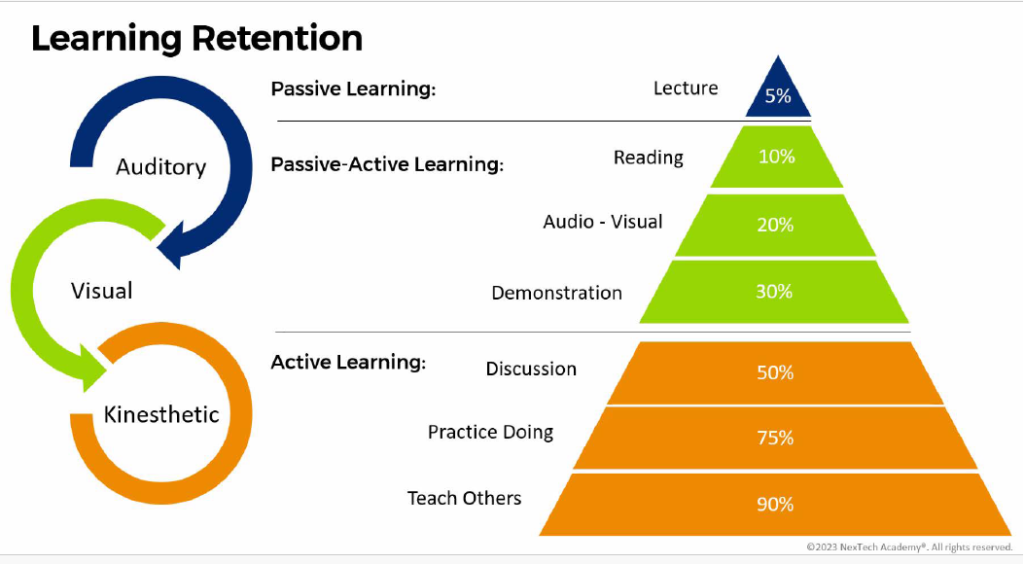

Another benefit to hands-on learning is the confidence that it builds in a technician. Seeing a confident technician changes everything for the homeowner. Hands-on learning also helps students retain information. At Nexstar, we use the Learning Retention Pyramid (see below).

When a student is simply sitting in a class, they’ll typically only retain about 5% of the knowledge taught. When you can have the students discussing, practicing, doing, and teaching others, that learning retention rate jumps to 50-90%. That’s why I prefer that members have equipment for us to work on when I do an onsite training – because working with the equipment is when the true learning happens.

Q: When Nexstar members schedule an onsite, what are they usually looking to accomplish?

A: Most of the time, when a member schedules an onsite with me, they have some challenges they’d like to overcome. Some of the most common items they want to tackle are callbacks, installation issues, and making sure their technicians are trained on what the company sells and works on. At Goods Electric, Heating, and Air in Ohio, for example, they wanted their young team to gain more knowledge so they could prevent callbacks in their department. They also wanted to streamline a Standard Operating Procedure (S.O.P.) that I created for their HVAC install and service departments.

Q: Given your knowledge and experience in the HVAC field, what are some of the focus areas that you teach at onsite training?

A: When a member books an onsite training with me, focus areas are a big topic. We plan for how I’ll be helping the member’s teams in these areas. Some of the most frequent areas that members want to focus on are reducing callbacks, getting their teams on the same page, and helping their service, maintenance, and installation teams to work more efficiently. After all, time is money.

Another area of focus is making sure some of the newer technicians understand the fundamentals of heating and cooling systems. When a technician is only taught by doing ride-alongs, they miss a lot of the “why” behind things, including the fundamentals.

Q: Once a Nexstar member schedules an onsite with you, Joe, what happens next?

- I typically have the members’ technicians take an HVAC technical aptitude test, which I created so that the members can see what their technicians currently know on a technical level. Then, I also have them take an opportunity survey, which breaks apart the trade into specific topics, and I go over those results with the member in a Zoom or Microsoft Teams meeting, and I enter the data into a SWOT[KB1] (Strengths, Weaknesses, Opportunities, and Threats) spreadsheet so we can all view the data in one place.

- Based on the assessments, I can then see what their technicians need to learn. I then create a customized agenda that shows which content is being taught, what times the blocks of training are, and whether the content is being taught in the classroom or the lab. Typically, I will do classroom instruction in the morning and lab (hands-on) in the afternoon.

- After we have gone over the agenda together and the dates are determined, I begin the planning stage for each day I will be there. If a company has a lot of technicians to train but doesn’t want to pull all their techs out of the field, I do a multi-day training, where I split the technicians into two teams. I then teach each team for 2 days; I do that to minimize the revenue hit for the member.

Q: What is the member’s role (or the training leader’s) in preparing for the onsite training?

A: What I typically need to uncover and prepare for is the following:

- KPIs – I want to know their team’s KPIs so I can see the bigger picture. (If it’s an install team, I would ask for a list of the last 60-90 days of callbacks, so I can see what the issues are.)

- Topics – I need to know what the member thinks the technicians need help with. Sometimes, technicians don’t know what they don’t know, or they may be nervous to tell their manager where they need help.

- Ride-Alongs – Are ride-alongs needed? I offer ride-alongs with technicians, if that’s what the members would like to plan. During these, I ride on actual calls in the field with technicians and coach them.

- Equipment/Tools – I ask the members if they have a lab or equipment ready to work on. If there’s not a lab, they can use some old or new equipment. When I did the onsite with Goods, Josh Barber spent the whole weekend prior setting up a lab. I was super grateful for that! However, this is not required.

- Revenue Loss – When you pull technicians out of the field for in-person training, it’s a revenue loss, and that must be a discussion topic among me and the member. At Goods, we decided to do a five-day training where I facilitated training for two groups: Half the service department on Monday and Tuesday and the other half of the service department on Wednesday and Thursday. On Friday morning, I spent time with lead technicians, and then I recapped with the leadership team and covered the next steps on Friday afternoon.

Q: What’s something you suggest that participants do in advance that will help enhance their training experience?

A: The first thing I’d suggest to a member is to have your techs take our assessments, so I can see what they know and where the weak spots are

Q: Once you’re onsite and the training begins, what does a typical day look like?

A: A typical training looks like this:

On the first day, we start at a set time. I go over a PowerPoint that covers who I am, what my background is, and what the objectives of the training are. I always like to do a group activity where I split the group up into table groups and ask techs what they’d like to learn. I have them put their answers on a big piece of paper and have them present what their team wants to get out of the training.

After that, I typically train in the classroom until lunch. After lunch, we do hands-on training on equipment or in the member’s lab.

I check in at the end of each day; we go over what we’ve learned, and we start crossing off items on the list of what the techs want to get out of the class. Each day gets more fun and personable as we establish a relationship and get to know each other. It’s really fun!

Q: At the end of training, what usually happens? Is there a test, or do participants receive a certification?

A: All of the classes I facilitate qualify for NATE credits. N.A.T.E. stands for “North American Technician Excellence,” and it’s a certification that an HVAC technician can hold and get CEUs toward recertifying. I give techs evaluations to fill out, so they can tell me how their training experience was; I also provide my personal cell number. If techs have issues in the field, I can be a source of tech support for them.

Q: What do you enjoy most about onsite training with member teams, Joe?

A: I love watching people learn. When I was a technician, and I was finally able to understand something, it made my job so much more enjoyable. The more techs understand, the more they grow in confidence. I enjoy seeing them grow and succeed!

Q: Any closing thoughts or insights you’d like to share?

A: Members typically don’t schedule onsite training with me in the summer because they’re so busy. That being said, if members are getting multiple callbacks or having KPI issues in their department with their technicians, summer is the best time to have me out, because the technicians can apply what they’ve learned immediately. Also, I encourage members to just reach out. They can book a call with me, and we can discuss their training needs.

Nexstar members, contact Joe at [email protected] to discuss your technical needs and to schedule an onsite training. If you are not a Nexstar member but curious to learn more about our mission to turn the world’s best tradespeople into the world’s best businesspeople, please click here.

Pulled Quote from Joe’s Onsite at Goods:

“Joe’s genuine interest in our team’s needs was evident from the beginning. He took the time to tailor the training program to ensure it was supportive and directly relevant. Throughout the training, Joe remained flexible to any changes or additional needs that arose along the way.

The feedback from our team praised Joe’s ability to hold their attention and make the material come alive. Many expressed a desire for more time with him, which is a testament to his effectiveness as an educator.

After the training was over, Joe ensured that all promised tools and materials were delivered promptly, further enhancing the value of the training experience. As a result of Joe’s efforts, our team’s confidence in their HVAC system inspection and diagnostic skills have noticeably increased, leading to tangible improvements in their performance.” – Dannie Erb, Operations Manager, Goods Electric, Heating & Air